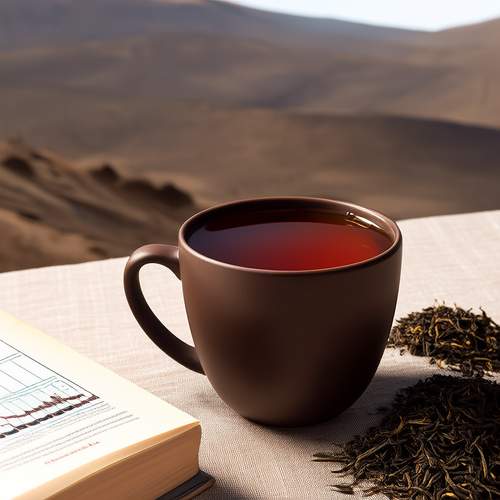

The world of specialty coffee is vast and nuanced, with each region offering distinct flavors and characteristics. Among these, Indonesian Mandheling coffee stands out for its rich, full-bodied profile and earthy undertones. One critical aspect that defines the quality of Mandheling coffee is the grading process, particularly the use of sieve sizes or screens to sort the beans. This meticulous practice ensures consistency and excellence, making it a cornerstone of Mandheling coffee production.

Mandheling coffee, grown in the lush highlands of North Sumatra, is renowned for its unique processing method known as "wet-hulling" or Giling Basah. This technique, combined with the region’s volcanic soil and tropical climate, contributes to the coffee’s signature flavor profile. However, even the finest beans must undergo rigorous sorting to meet international standards. This is where the use of sieve screens becomes indispensable.

The sieve grading system for Mandheling coffee involves passing the beans through a series of screens with standardized hole sizes. These screens, typically measured in increments of 1/64 of an inch, separate the beans by size. Larger beans, often associated with higher quality, are sorted into premium grades, while smaller beans may be classified for domestic use or blended into lower-grade exports. The most common sieve sizes for Mandheling coffee range from Screen 15 to Screen 18, with Screen 18 being the largest and most sought after.

Why does size matter? The correlation between bean size and quality is a topic of much debate in the coffee industry. While larger beans are generally believed to have developed more fully and uniformly, size alone does not guarantee superior flavor. However, in the case of Mandheling coffee, the sieve grading process serves as a practical indicator of density and consistency—two factors that significantly impact roast uniformity and, consequently, flavor extraction.

The traditional sieve grading method is labor-intensive but highly effective. After harvesting, the coffee cherries are pulped, fermented, and dried to a moisture content of around 30-35%. The beans are then hulled, revealing the green coffee inside, and sorted manually or mechanically. Workers meticulously remove defects, such as broken or discolored beans, before the remaining beans are passed through the screens. This step ensures that only beans of similar size and density make it into the final batch.

For exporters and roasters, the sieve size of Mandheling coffee is more than just a number—it’s a mark of quality assurance. Buyers often specify their preferred screen size based on their roasting techniques and desired flavor profiles. A larger bean, such as those from Screen 18, may roast more evenly and develop a deeper, more complex flavor, while smaller beans might be preferred for certain espresso blends where consistency in extraction is key.

The cultural significance of sieve grading in Mandheling coffee production cannot be overstated. This practice is deeply rooted in the region’s coffee-growing heritage, passed down through generations of farmers. It reflects a commitment to quality that has helped Mandheling coffee maintain its reputation as one of the world’s finest. In recent years, however, advancements in technology have introduced automated sorting machines, which can process beans faster and with greater precision. Despite these innovations, many producers still rely on traditional methods, believing that the human touch adds an irreplaceable layer of care to the process.

Climate change and shifting market demands pose challenges to the future of Mandheling coffee production. Unpredictable weather patterns can affect bean size and yield, making consistent grading more difficult. Meanwhile, the rise of specialty coffee culture has increased demand for transparency and traceability, pushing producers to adopt more stringent quality control measures. Sieve grading remains a vital tool in meeting these expectations, ensuring that every batch of Mandheling coffee lives up to its storied legacy.

For coffee enthusiasts, understanding the role of sieve sizes in Mandheling coffee offers a deeper appreciation of the journey from farm to cup. It’s a reminder that behind every sip of this bold, syrupy brew lies a meticulous process designed to deliver excellence. Whether you’re a home brewer or a professional barista, paying attention to bean size can elevate your coffee experience, allowing you to savor the true essence of Sumatran terroir.

In the end, the sieve grading system is more than just a technical step in coffee production—it’s a testament to the dedication of Indonesian coffee farmers and their unwavering pursuit of quality. As the global coffee community continues to evolve, the principles behind this practice will undoubtedly remain a cornerstone of Mandheling coffee’s enduring appeal.

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025

By /May 26, 2025